Acid gas, also known as amine overhead gas, is a blend of acidic gases including carbon dioxide (CO2) and hydrogen sulfide (H2S), and a common byproduct of various industrial processes, including natural gas processing, refining and chemical production. These gases are considered “acidic” because they can dissolve in water to form acids, leading to a decrease in pH when released into the environment. These gases, known for their corrosive properties, pose significant risks to the environment, human health and industrial equipment if not properly managed.

Where Acid Gas Comes from – Amine Sweeting

In many industrial settings dealing with sour gas, sweetening processes are employed to remove hydrogen sulfide (H2S) using methods like amine scrubbing. Amine gas treating, or sweetening, is frequently used in high volume applications, such as natural gas processing plants and refineries. Amine sweetening systems, however, generates an acid gas stream that requires careful handling and disposal.

Traditional Acid Gas Disposal Methods (Pros/Cons)

Traditional methods of disposing of acid gas include flaring and injection into specialized Acid Gas Injection (AGI) wells.

Flares and Enclosed Combustors:

- Pros: Flaring is simple and can use existing infrastructure.

- Cons: Key drawbacks include the fact that flaring may not be a permitted use in some jurisdictions and burning acid gas produces harmful SO2 emissions.

Acid Gas Injection (AGI) Wells:

- Pros: Can be safe and a permanent solution.

- Cons: AGI may not be permitted in some jurisdictions, permitting may take 1-3 years, if at all. Additionally, it is expensive to get started and requires ongoing monitoring of the potential impact on groundwater and other long-term environmental concerns. AGI wells also present a potential single point of failure, increasing the risk of unplanned downtime.

Liquid Redox for Acid Gas Treating

Next generation Liquid Redox technology offers a revolutionary approach to acid gas treatment by utilizing a Reduction-Oxidation (Redox) chemical reaction. Acid gas containing H2S exits the Liquid Redox system sweet (without H2S) and the elemental sulfur is filtered out of the regenerated chemistry where it can be reused, further reducing costs. The sulfur can be used for organic food production. This process not only eliminates the need for flaring or AGI but also delivers pure CO2 for carbon capture and storage (CCS).

- Pros: Eco-friendly, eliminate flaring, eliminate AGI, cost-effective, deliver pure CO2 for CCS or industrial use.

- Cons: None.

READ MORE: Streamline’s Sulfur from H2S Receives Listing as an input for Organic Food Production

VALKYRIE® Acid Gas Treating Units – Leveraging the Power of Liquid Redox Technology

VALKYRIE Acid Gas Treating Units (AGTUs) harness reliable, proven next generation Liquid Redox technology to deliver an eco-friendly solution to disposing of acid gas generated from H2S sweetening processes.

VALKYRIE AGTUs deliver these benefits:

- Seamlessly integrate with existing H2S removal processes.

- Can operate from 0-30 psig.

- Can handle extremely high H2S concentrations (more than 80%).

- Offer little to no pressure drop across the unit.

- Effectively eliminates all remaining H2S from the gas stream and delivers elemental sulfur.

- Ensure compliance with regulatory standards.

LEARN MORE: VALKYRIE® Gas Treating Technology

READ MORE: Streamline’s Sulfur from H2S Receives Listing as an input for Organic Food Production

CCS Benefits

VALKYRIE AGTUs using next generation Liquid Redox chemistry deliver a multitude of benefits to CCS efforts:

- Eliminates flaring of acid gas and associated emissions.

- Eliminates need for an Acid Gas Injection (AGI) well.

- Delivers pure CO2 for multiple uses, including CCS.

- Pure CO2 for CCS increases storage capacity and maximizes carbon credits (45Q tax credit) .

- Qualify for clean energy tax credits.

LEARN MORE: 45Q Tax Credit for Carbon Oxide Sequestration

LEARN MORE: IRA (Inflation Reduction Act) Tax Credit

The VALKYRIE Acid Gas Treating Advantage

VALKYRIE stands out as a true green solution with its use of non-toxic, eco-friendly chemicals and renewable or low-impact resources. Its energy efficiency, reduced waste generation, and compliance with regulations make it a cost-effective and environmentally responsible choice for acid gas treatment.

Advantages of VALKYRIE AGTUs for acid gas treating:

- A true green solution with non-toxic and eco-friendly chemicals

- Renewable or low-impact resources

- Energy efficiency

- Reduced waste and generation of byproducts

- No harmful byproducts

- Recyclability or reusability

- Cost-effectiveness

- Compliance with regulations

Summary

VALKYRIE liquid redox technology offers a sustainable and efficient solution for treating acid gas, mitigating environmental risks, and promoting carbon capture initiatives. By harnessing the power of chemistry, it not only addresses industrial challenges but also paves the way for a greener, more sustainable future.

Contact us today to learn more about Next Generation Liquid Redox H2S treating technology and determine if the VALKYRIE system is right for your operation.

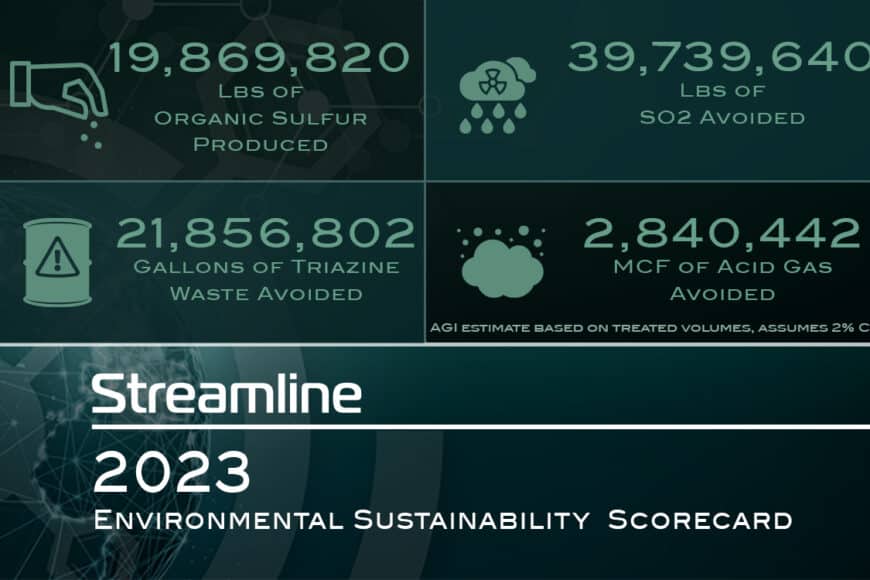

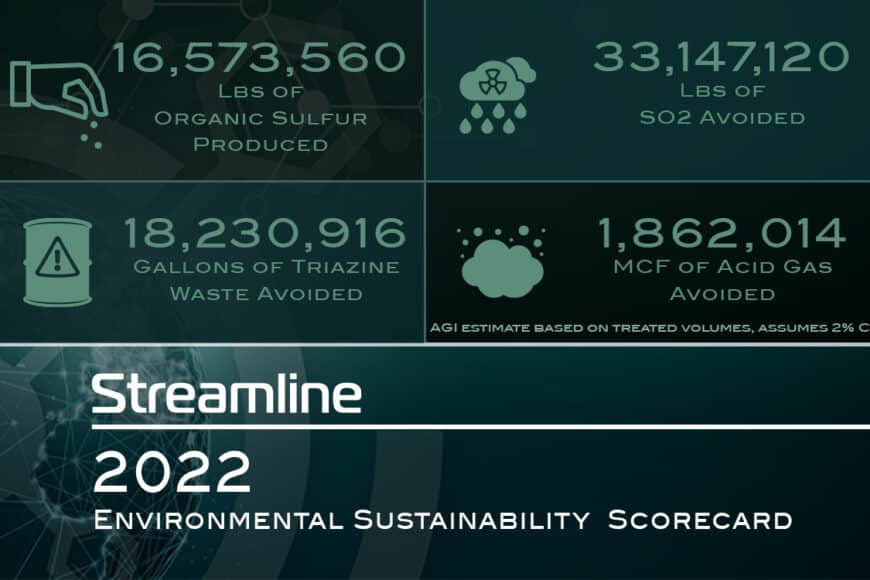

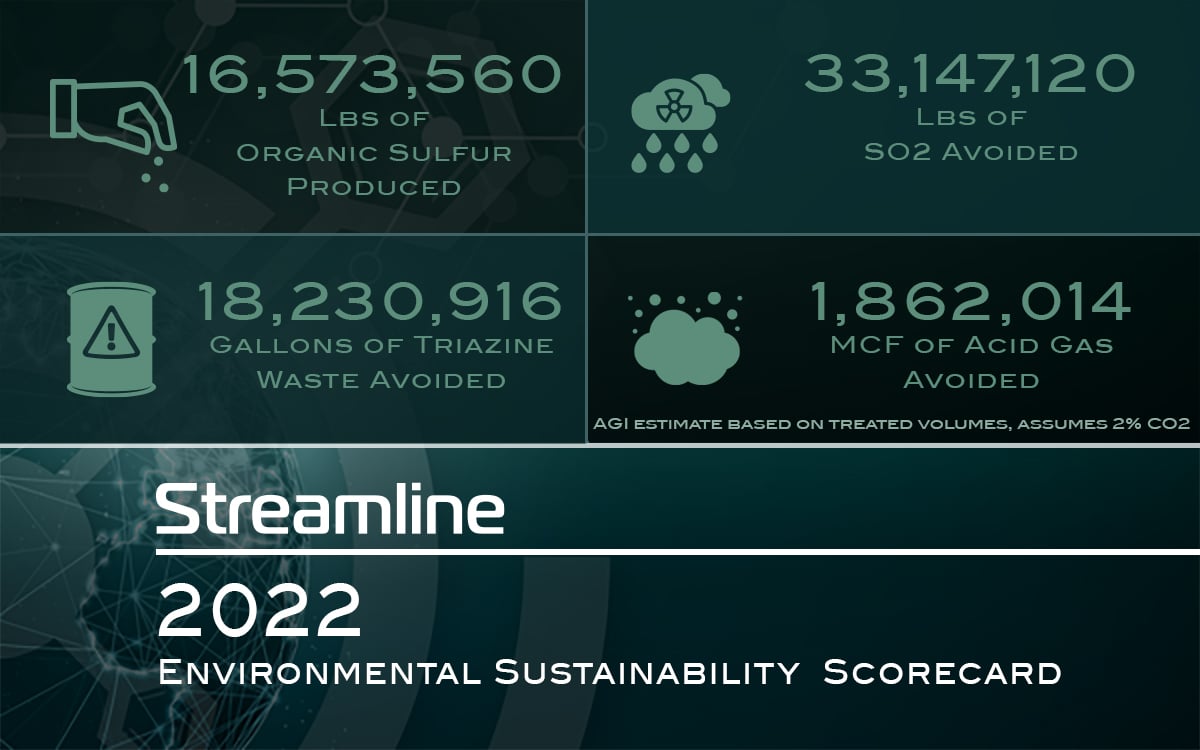

About Streamline Innovations

Streamline Innovation’s vision is Eliminating Emissions Through Technology. We help heavy industry around the world achieve environmental performance objectives, improve sustainability, and transition to a sustainable, low-carbon economy.

H2S is present in almost every industrial process in the world. Our technology can be applied across industries, delivering a sustainable solution that eliminates H2S, the leading cause of acid rain, a deadly greenhouse gas dangerous for work and living environments.

Streamline believes that achieving the E (“Environmental”) in ESG requires data. Creating intelligent systems that operate effectively and efficiently without human intervention is critical to reducing emissions that harm the environment. We integrate advanced data collection, process control, and analytics in our technologies to provide a total solution for customers.

We serve organizations in multiple sectors, including Energy/Oil & Gas, Biogas, Landfill Gas & Renewable Fuels, Municipal Wastewater and Industrial Air & Water.